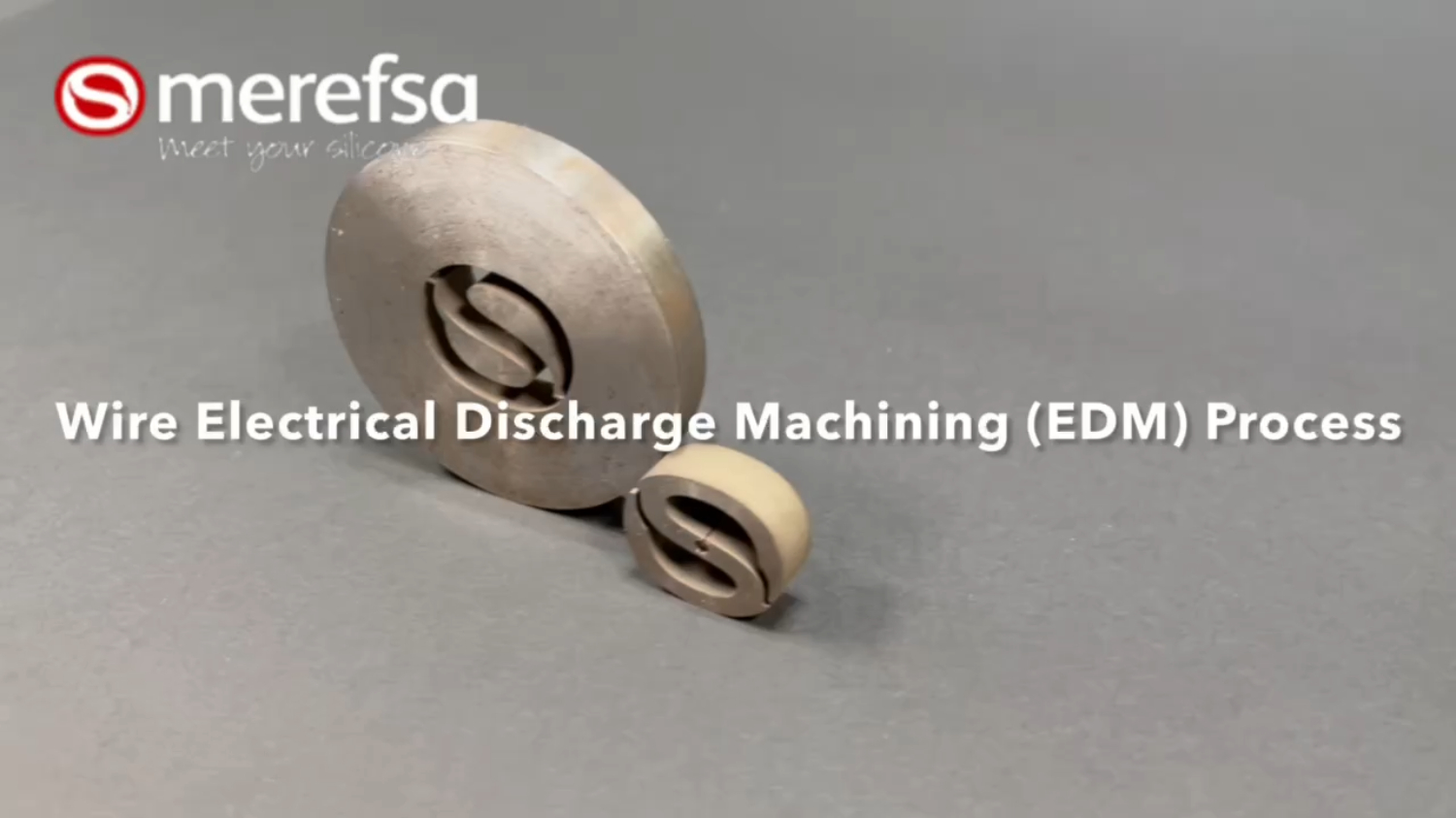

Hole drilling EDM process

In the link below we show you the high-speed drilling process we perform in our machining plant. With this +GF+ EDM hole drilling machine with fine electrode technology, we drill the necessary starting holes to continue with the manufacturing process of metal parts machined with wire EDM technology. Electrical discharge machining (EDM) is an extremely precise manufacturing process that uses electrodes, dielectric fluid and an electric current to cut metals.

You can see simple hole drilling in multiple configurations. The AgieCharmilles DRILL 20 is a high-speed drilling machine used to drill starter holes. With its five-axis configuration, the machine can drill holes up to 200 mm at any angle in a workpiece with an inclined surface. In this video we show the drilling of a hole in a metal part, which is the preliminary step in the process of making the die for the wire EDM extruder nozzle.

Drilling holes in multiple configurations, Merefsa does it.

We show you how we start the hole punching process that allows us to manufacture the dies for our silicone profiles.