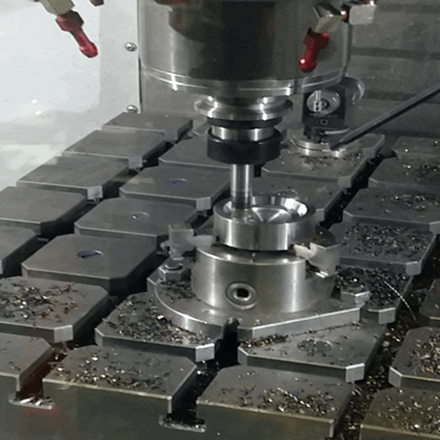

Machining

Milling consists of using a cutting tool that removes layers of material from a workpiece until it reaches the desired shape and dimensions. Material removal can be performed through abrasion using a grinding wheel or by chip removal, initially removing large amounts of material and finishing with precise erosion of smaller amounts. The cutting tools used must have the appropriate hardness, rigidity, and thermal properties to ensure the success of the process.

Machining Solutions at Merefsa

We have the necessary technology for manufacturing parts, dies, and molds used in all our production processes.

Our state-of-the-art machinery park includes:

- Manual and automatic lathes with motorized tools.

- 4-axis vertical machining center.

- 5-axis simultaneous machining center.

- Wire EDM machines.

Customer Service Improvements

Having advanced technology in our Machining Plant allows us to manufacture automatically and flexibly using EDM and CAD/CAM, which optimizes the production of tooling and molds.

The advantages we offer our customers include:

- Short lead times for final products.

- Continuous improvement in the quality of molds, profiles, and parts.

- Commitment to guaranteeing precise tolerances (up to 3 microns).

Common Machining Products and Materials Used

For tooling manufacturing, we mainly use tool metals such as iron, stainless steel, and aluminum. We are also specialists in the machining of technical plastics, with experience in the custom manufacturing of PTFE parts.

Some of our most common products include:

- Molds.

- Profiles.

- Metal parts.

- PTFE parts: balls, gaskets, joints, segments, etc.