Silicone in the machinery sector (OEM)

Silicone is widely used in machinery due to its versatility, durability, and ability to adapt to any type of mechanism.

Its excellent performance against heat, abrasion, deformation, aging, and permeability guarantees a long service life even in demanding environments. It is used in a wide range of formulations tailored to different needs: standard insulating silicone (MVQ), conductive silicone, steam silicone, fluoro silicone (FVMQ), very high-temperature silicone (THT), very low-temperature silicone (PMVQ), platinum silicone, and food-grade silicone compliant with FDA regulations (CFR21 section 177.2600) and BgVV (Recommendation XV).

At MEREFSA, we design and customize silicone solutions to meet the specific needs of each client, ensuring performance and quality in every application.

Silicone Strengths

Mechanical and Electrical: Silicone offers high resistance and excellent performance against deformation, making it ideal for absorbing impacts, ensuring sealing, and maintaining impermeability against dust, salt, and other climatic agents. It is also used for coating cables, providing reliable and durable electrical insulation.

Thermal: Its resistance to temperatures from -60 °C to +300 °C makes it an essential material for sealing components, fluid circulation, and joints in combustion processes, ensuring stability and performance even in extreme conditions.

Chemical: Thanks to specific formulations of hardness, color, and transparency, silicone adapts to any design or technical requirement. Fluorinated silicone stands out for its high-temperature resistance and its ability to withstand corrosion, making it suitable for applications where other silicones are ineffective. Fluorosilicones also offer resistance to most solvents, expanding their range of applications.

Where is it used?

Silicone is widely used in industrial applications for its resistance and adaptability. It is key in sealing mechanisms, in welding processes in the packaging industry, in autoclaves for industrial sterilization, in fluid transfer, and in the transportation of semi-finished products.

It is also used for insulating electrical and electronic systems from external agents and in rollers for conveyor belts.

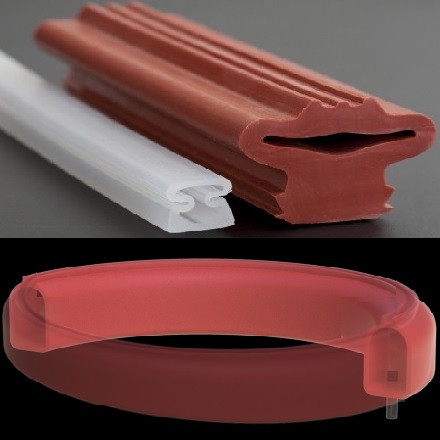

Specifically in: Tubes for protection and cable passage, high-temperature silicone profiles for packaging welding, inflatable seals for autoclaves, stoppers, tubes and sleeves for liquid exchange, vibration dampers, seals for sealing processes, silentblocks, and reinforced silicone tubes for high-pressure processes.

Applied Products