FEP or PFA encapsulated Silicone or FKM gaskets

- Product Information

- Images

- Available Products

At MEREFSA, we offer a wide variety of encapsulated silicone seals, designed to ensure high performance in demanding applications. We provide models encapsulated in FEP, PFA, and PTFE, in various formats such as O-ring, rectangular, or oval, as well as options with Camlock closures, adapting to the specific needs of each industrial application.

Product Information

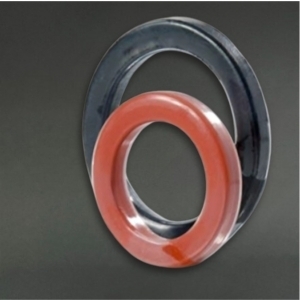

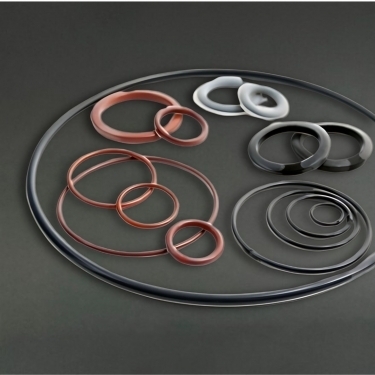

Encapsulated Seals of high quality, designed for applications that require optimal sealing. We offer encapsulated seals in FEP or PFA with a silicone, FKM, or EPDM core, in various formats such as O-ring, square, rectangular, oval, and with Camlock closures.

These seals can be manufactured in solid or hollow versions, with no diameter limitations for O-rings.

When to use Silicone Encapsulated Seals?

They are the ideal solution for applications where the use of conventional rubbers is prohibited, such as in the food, chemical, and pharmaceutical industries. In environments where corrosion or high temperatures may prematurely degrade O-rings, compromising their sealing capability, silicone encapsulated seals offer greater resistance and durability, ensuring optimal long-term performance.

When to use FKM encapsulated gaskets?

They are recommended for applications that require high resistance to corrosion and extreme temperatures, both high and low. They are particularly suitable for environments where the use of conventional rubbers is prohibited due to the presence of aggressive substances such as acids, solvents, and hydrocarbons. In these cases, the use of encapsulated FKM O-rings prevents premature deterioration and ensures the system's sealing integrity.

Material Comparison for O-Rings

Pure PTFE O-Rings: PTFE is an inert material with excellent chemical resistance. However, due to its rigidity and lack of elastic memory, it is not suitable for use as a compression seal. Once disassembled, the seal loses its sealing capability, which limits its reusability.

PTFE Sandwich Seals: While they are a cost-effective option, their design features high permeability on the sides, which reduces their effectiveness and makes them vulnerable to chemical attacks. This makes them a less durable solution in demanding applications.

PTFE Coated O-Rings: O-rings coated with acrylic or latex emulsions with PTFE offer a low friction coefficient. However, they lack significant chemical resistance, and their coating deteriorates easily, which limits their usefulness in aggressive industrial environments.

Perfluoroelastomer O-Rings: This material represents the most advanced solution in terms of chemical resistance and operational temperature range. However, its high cost limits its viability for many industrial applications, being reserved only for critical situations.

Metal O-Rings: These offer excellent chemical resistance and optimal performance in high-pressure applications. However, their rigidity and high cost can be drawbacks in certain applications where greater flexibility is required.

Encapsulated Seals: Flexibility + Resistance

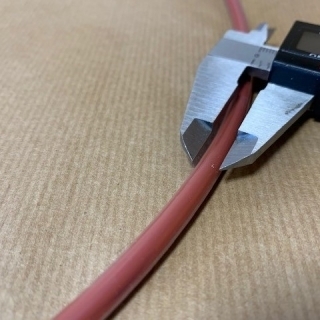

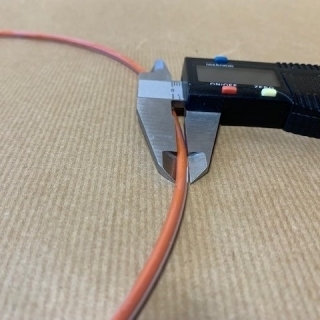

Silicone Encapsulated O-Rings: Designed for static applications, combining the chemical resistance of FEP or PFA with the flexibility of a silicone core. They are recommended for applications that require FDA certification or contact with food, as silicone allows for a temperature range of -60 °C to +260 °C. The FEP coating offers good chemical resistance, although with a more limited temperature range, while PFA withstands temperatures up to +260 °C and provides greater resistance to abrasion and pressure.

FKM Encapsulated O-Rings: Designed for static applications, these encapsulate a fluoroelastomer (FKM) core in FEP or PFA, offering an optimal combination of chemical resistance and flexibility. The FKM core, with a temperature range of -20 °C to +204 °C, provides superior chemical resistance compared to silicone. As with silicone encapsulated seals, the FEP coating limits its temperature range, while PFA, with thermal stability up to +260 °C, ensures greater resistance to abrasion and pressure.

Available in multiple formats (O-ring, square, rectangular, oval, and with Camlock closures), these seals can be manufactured in solid or hollow versions. Additionally, we offer O-rings with no diameter restrictions, adapting to the specific needs of each client.

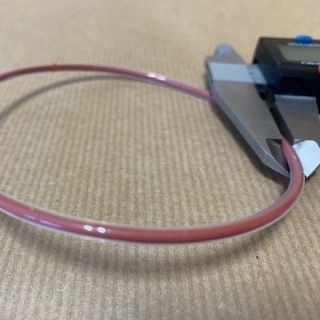

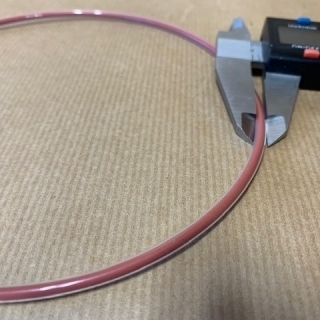

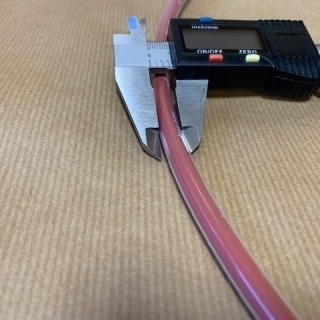

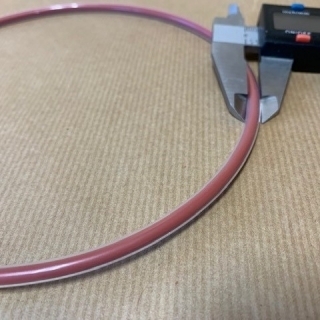

Images

-

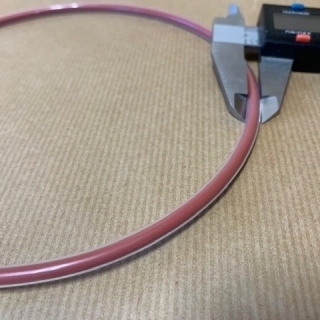

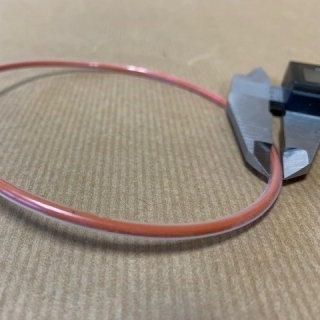

ENCAPSULATED FEP+SILICONE Øi 640 mm X Ø 4 mm C.S.

| Stock: 1 U | P.V.P.: 50,40 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI64004

SHOPStock: 1 U -

ENCAPSULATED O-RING FEP + SILICONE Øi 122 mm X Ø 6 mm C.S.

| On request | P.V.P.: 18,10 € / U (VAT not included) | Term: Request | Ref. TFEPSI01220060

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONA Øi 507 mm X Ø 6 mm C.S.

| Stock: 1 U | P.V.P.: 47,52 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI50706

SHOPStock: 1 U -

ENCAPSULATED O-RING SILICONE FEP+SILICONA Øi 480 mm X Ø 6 mm C.S.

| Stock: 4 U | P.V.P.: 42,62 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI48006

SHOPStock: 4 U -

ENCAPSULATED O-RING FEP+ SILICONE Øi 25 mm X Ø 5 mm C.S.

| Stock: 18 U | P.V.P.: 10,95 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0025050

SHOPStock: 18 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 66 mm X Ø 5 mm C.S.

| Stock: 1 U | P.V.P.: 12,41 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0066050

SHOPStock: 1 U -

ENCAPSULATED O-RING FEP+SILICONE Ø 12.8 mm X Ø 2.5 mm C.S.

| Stock: 3 U | P.V.P.: 8,26 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0128025

SHOPStock: 3 U -

ENCAPSULATED O-RING FEP+SILICONE Ø 2030 mm X Ø 6.99 mm C.S.

| Stock: 2 U | P.V.P.: 184,00 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPS2060699

SHOPStock: 2 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 288 mm X Ø 5 mm C.S.

| Stock: 5 U | P.V.P.: 21,12 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0288050

SHOPStock: 5 U -

ENCAPSULATED O-RING FEP+ VITON Øi 139.37 mm x Ø 2.62 mm C.S.

| Stock: 2 U | P.V.P.: 15,05 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPVI013940262

SHOPStock: 2 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 202.79 mm X Ø 3,53 mm C.S.

| Stock: 5 U | P.V.P.: 13,92 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI20280353

SHOPStock: 5 U -

ENCAPSULATED O-RING FEP + SILICONE Øi 370 mm X Ø 10 mm C.S.

| Stock: 10 U | P.V.P.: 43,51 € / U (VAT not included) | Term: 20/23 days (Manufacturing) | Ref. TFEPSI03700100

SHOPStock: 10 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 115 mm X Ø 2.5 mm C.S.

| Stock: 4 U | P.V.P.: 8,40 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0115025

SHOPStock: 4 U -

ENCAPSULAET O-RING FEP+SILICONE Ø 92 mm X Ø 3 mm C.S.

| Stock: 3 U | P.V.P.: 9,39 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0092030

SHOPStock: 3 U -

ENCAPSULATED O-RING FEP + VITON Øi 81,92 mm X Ø 5,33 mm C.S.

| Stock: 50 U | P.V.P.: 18,04 € / U (VAT not included) | Term: 7/10 days (Manufacturing) | Ref. TFEPVI00819053

SHOPStock: 50 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 1798 mm X Ø 8 mm C.S.

| Stock: 2 U | P.V.P.: 176,05 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI179808

SHOPStock: 2 U -

ENCAPSULATED O-RING FEP + SILICONE Øi 370 mm X Ø 9 mm C.S.

| Stock: 10 U | P.V.P.: 39,56 € / U (VAT not included) | Term: 20/23 days (Manufacturing) | Ref. TFEPSI03700090

SHOPStock: 10 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 455 mm X Ø 6 mm C.S.

| On request | P.V.P.: 42,62 € / U (VAT not included) | Term: Request | Ref. TFEPSI45506

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 230 mm X Ø 3.53 mm C.S.

| Stock: 4 U | P.V.P.: 14,50 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI02300353

SHOPStock: 4 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 132,94 mm X Ø 3,53 mm C.S.

| Stock: 8 U | P.V.P.: 10,72 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI1329035

SHOPStock: 8 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 110 mm X Ø 4 mm C.S.

| Stock: 4 U | P.V.P.: 11,55 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0110040

SHOPStock: 4 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 84 mm X Ø 3 mm C.S.

| Stock: 4 U | P.V.P.: 9,16 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0084030

SHOPStock: 4 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 304.14 mm X Ø 6.99 C.S.

| On request | P.V.P.: 27,31 € / U (VAT not included) | Term: Request | Ref. TFEPSI30414070

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 142.47 mm X Ø 3.53 mm C.S.

| On request | P.V.P.: 11,18 € / U (VAT not included) | Term: Request | Ref. TFEPSI14240353

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 1922 mm X Ø 5 mm C.S.

| On request | P.V.P.: 165,86 € / U (VAT not included) | Term: Request | Ref. TFEPS192205

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 253.37 mm X Ø 6. 99 mm C.S.

| Stock: 2 U | P.V.P.: 24,14 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI25337070

SHOPStock: 2 U -

ENCAPSULATED O-RING EP+SILICONA Øi 542 mm X Ø 8 mm C.S.

| Stock: 5 U | P.V.P.: 55,10 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0542080

SHOPStock: 5 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 200 mm X Ø 5 mm C.S.

| Stock: 1 U | P.V.P.: 16,34 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0200050

SHOPStock: 1 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 95 mm X Ø 5 mm C.S.

| Stock: 3 U | P.V.P.: 11,39 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0095050

SHOPStock: 3 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 157 mm X Ø 5 mm C.S.

| On request | P.V.P.: 13,71 € / U (VAT not included) | Term: Request | Ref. TFEPSI15705

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 42 mm X Ø 3 mm C.S.

| Stock: 3 U | P.V.P.: 7,96 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI0042030

SHOPStock: 3 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 220 mm X Ø 5 mm C.S.

| On request | P.V.P.: 18,20 € / U (VAT not included) | Term: Request | Ref. TFEPSI0220050

SHOPOn request -

ENCAPSULATED O-RING FEP+SILICONE Øi 786 mm X Ø 10 mm C.S.

| Stock: 2 U | P.V.P.: 105,30 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI78610

SHOPStock: 2 U -

ENCAPSULATED O-RING FEP+SILICONE Ø 114 mm X Ø 3,55 mm C.S.

| Stock: 12 U | P.V.P.: 9,84 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI01140355

SHOPStock: 12 U -

ENCAPSULATED O-RING FEP+SILICONE Øi 91.67 mm X Ø 3 mm C.S.

| Stock: 1 U | P.V.P.: 9,40 € / U (VAT not included) | Term: 1/3 days | Ref. TFEPSI009167030

SHOPStock: 1 U

On request

If the product is not available, please indicate the features you need ...