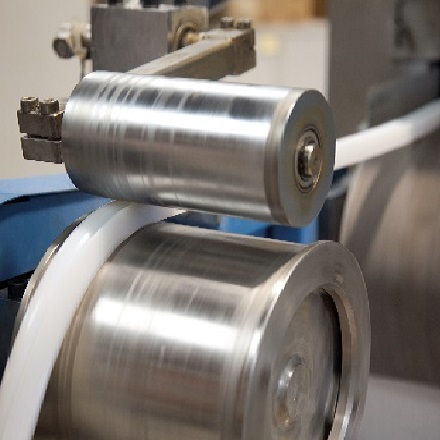

Silicone extrusion process

The silicone extrusion process consists of displacing uncured rubber through an extruder, where it is shaped according to the designed profile and then vulcanized at high temperature, fixing its physical and chemical characteristics. Wall thickness and quality are controlled without contact using a state-of-the-art reader and 4 artificial vision cameras, ensuring the highest tolerance levels.

We also offer the service of marking profiles or silicone tubes, incorporating text or numbering using high-precision inkjet printers.

Recently, we have acquired a state-of-the-art extrusion line, which allows us to improve service quality, reduce delivery times, and expand our range of products, including sponges of various densities.

Most Common Silicone Extrusion Products

Silicone Extrusion Tolerances at Merefsa, Standards, and Certifications

Tolerances in the silicone extrusion process depend on several factors, such as compound additives, temperature, curing time, and shrinkage, unlike more rigid materials.

There are three internationally recognized extrusion tolerance grades:

- Class E1 = Maximum Quality.

- Class E2 = Good Quality (Merefsa Standard).

- Class E3 = Non-Critical.

Atoxicity Guarantee

In our laboratory, we ensure compliance with silicone atoxicity regulations, meeting international standards for medical, pharmaceutical, and food contact use, according to the following regulations:

- FDA CFR 177.2600 (US Food and Drug Administration).

- BgVV BfR Cap. 15 (Federal Institute for Health Consumer Protection and Veterinary Medicine).

- USP Class VI (US Pharmacopoeia).

- EC Regulation 1935/2004.

- Journal officiel de la République Française Brochure 1227.

Advantages of the Extrusion Process

- Manufacture of a wide variety of shapes.

- Production in series with customized lengths according to customer needs.

- Exceptional service time from order reception to finished product delivery.