Laboratory and quality in Merefsa

The Merefsa Quality Department is responsible for controlling and ensuring the quality of finished products throughout the entire production process. This team applies the ISO 9001 standard, which establishes the requirements for Quality Management Systems (QMS).

We have the necessary mechanisms, actions, and tools to identify errors and ensure that all our products meet the required quality standards. To meet these specifications, key data is collected and analyzed, which is subsequently shared with the different departments to implement the corresponding corrective actions.

Product Control at Merefsa

Our manufacturing process, supported by an ERP system, allows us to guarantee the documentary traceability of our products, from raw material to the final piece.

At Merefsa, we supervise each stage of the production process, which allows us to offer exceptional quality. We rigorously control the characteristics of each product through sampling inspections. Products that do not meet the minimum quality specifications are discarded, ensuring that only compliant products reach our customers.

Our Laboratory Team

Our laboratory is equipped with the most advanced quality control tools on the market, along with a team of highly qualified professionals with extensive experience in the sector. This allows us to guarantee maximum accuracy in the issuance of reports on both the raw materials used and the final product manufactured.

We have the latest generation of:

- Oscillating disc rheometer.

- Durometer.

- Density meter.

- Dynamometer.

- Profile projector.

In addition, with Profile Master, we offer continuous quality traceability, supported by 4 artificial vision cameras for detailed and precise inspection.

Formulation Development

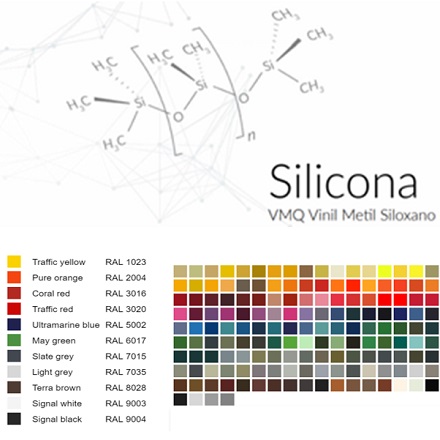

Our team of chemists continuously develops new formulations with silicone and other rubbers, offering customized solutions for each of our clients.

Some of the characteristics of our formulations include:

- Curing with platinum or peroxide salts.

- Shore A hardness range from 20˚ to 85˚ in VMQ silicone.

- Silicone foam density from 0.15 g/cm³ to 0.80 g/cm³.

- Possibility of incorporating various additives, such as HT (for temperatures above 250ºC), THT (for temperatures above 300ºC), steam additives, conductivity, high mechanical resistance, high transparency, and fluorosilicone.

- COLOR solutions, adapting to the desired transparency and the RAL number required for the final product.

Non-Toxicity Guarantee

In our laboratory, we review and guarantee compliance with silicone non-toxicity regulations, ensuring that our products meet the highest international standards for medical, pharmaceutical, and food contact use.

Among the regulations we follow are:

- FDA CFR 177.2600 (US Food and Drug Administration).

- BgVV BfR Cap. 15 (Bundesinstitut für Gesundheitlichen Verbraucherschutz Und Veterinärmedizin).

- USP Class VI (US Pharmacopoeia).

- Regulation EC 1935/2004.

- Journal officiel de la République Française Brochure 1227.