Merefsa cutting process

The cutting process refers to the division of materials such as silicone, PTFE, and others by applying pressure, with the aim of obtaining the final product according to the required specifications.

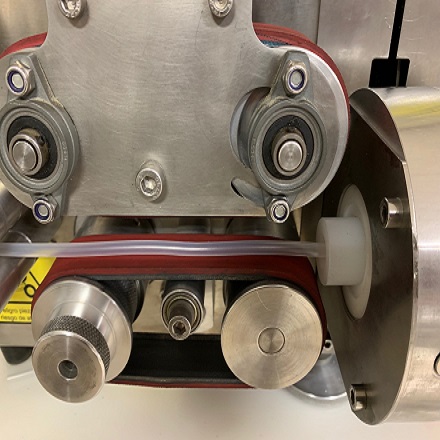

At Merefsa, we focus on continuously improving quality and customer satisfaction, so we allocate resources and prioritize investments in this area. We have advanced cutting machinery, including plotters, beam and bridge die-cutting machines, automatic continuous horizontal cutting machines, continuous orbital cutting machines, and high-precision automatic cutting bands, with a capacity of up to 4 meters.

Although our specialty is silicone and PTFE, we also supply flat die-cut gaskets or washers in various types of rubber (FKM, SBR, NBR, EPDM, CN, CR, PU, etc.), technical plastics (PA, PE, PP, PVC, TVT, etc.), and compressed cardboard. The most common standards we follow are DIN, ASA, ASME, and API. Depending on the selected material, our gaskets may be suitable for food contact use.

Types of Cutting and Available Machinery at Merefsa

We have a wide range of cutting equipment, including plotters, die-cutting machines, shears, and inline cutters, capable of processing rubber and plastic products with thicknesses of up to 15 mm. We also have a wide selection of molds and stamping dies.

We offer profile and tube cutting in thicknesses from 1 mm to any other size, using the following techniques:

- Continuous cutting.

- Orbital cutting.

- Flat cutting (die-cutting, plotter).

Most Common Cutting Process Products and Materials Used

We have our own section dedicated to the manufacture of molds, tooling, and dies, which allows us to offer fast service with reduced delivery times and highly competitive prices. Our team is composed of highly specialized personnel in the manufacturing, cutting, and welding of any type of flat gasket, using advanced machinery to meet the specific requirements of each customer.

We manufacture flat gaskets and washers in a wide variety of materials, as well as sleeves made of tubes or

shaped profiles:

- Silicone, compact silicone sheet and sponge sheet.

- Compressed cardboard.

- Expanded PTFE and PTFE sheet.

- Treated PTFE film + Silicone.

- PTFE-impregnated glass fabric.

- Silicone-coated glass fabric.

- Fluorinated rubber / FKM.

- Rubber / EPDM / Nitrile / Natural rubber.

Silicone Cutting Tolerances, Standards, and Certifications

At Merefsa, we guarantee maximum precision in all our cutting and tolerance processes, allowing us to offer the widest range of rubber gaskets with the best quality and the most competitive prices on the market.

There are three types of longitudinal cutting tolerance ("L"):

- Class L1 = Maximum Quality.

- Class L2 = Good Quality.

- Class L3 = Non-Critical.

Standards and Certifications: We ensure that our products comply with general standards and the most stringent certification regulations in manufacturing, including:

- ISO 9001 and ISO 14001

- TS 16949, UNE-EN ISO 13485, OHSAS 18001

- ISO 3302-1

Additionally, we have implemented automatic inline cutting with laser and ERP integration, which allows us to customize the length of rolls for each silicone extrusion order. We have also incorporated Online Certification Software (Report Manager), allowing direct download of dimensional certifications.