Silicone Molding and Welding

Molding is the process of melting and modifying a material to introduce it into a mold in order to obtain a final product with a specific shape.

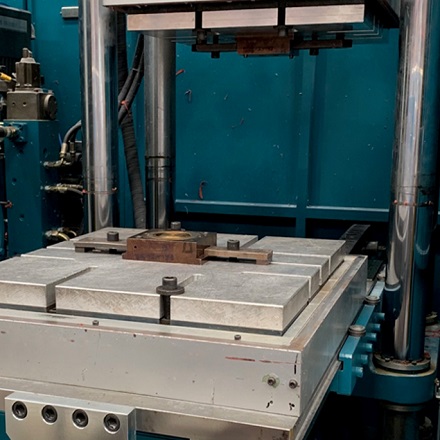

At Merefsa, we carry out this process through compression and injection molding.

- Injection Molding: This process consists of injecting silicone at high pressure into a mold to create parts with pre-designed and machined geometries. In addition to standard injection, we offer other molding techniques, such as co-injection, bi-injection, and overmolding, which are selected according to the characteristics of the final product.

- Compression Molding: In this process, silicone is placed in an open mold at high temperature, and pressure is applied so that it acquires the desired shape while vulcanizing efficiently with heat.

Molds at Merefsa

At Merefsa, we have single or multi-cavity molds, depending on the choice of our Design Department, which selects the most suitable option to optimize costs and service times. The molds are usually made from tool metals, such as iron, stainless steel, and aluminum. We have our own machining section for the manufacture of molds, tools, and dies, using advanced equipment such as EDM machines, milling machines, CNC lathes, digital control lathes, and automatic lathes.

Molding Solutions at Merefsa

We manufacture samples, prototypes, and large series, offering customized solutions with any hardness, color, and additive required. Our hot compression molding and welding process allows us to produce parts based on a plan or sample, in small, medium, or large series, with or without textile, metal, or bi-component inserts. Additionally, silicone parts are post-cured in a hot air oven with forced circulation after vulcanization, ensuring greater durability and precision.

Welding Process

At Merefsa, we have extensive know-how in profile welding, using our own technology for the production and development of our molds and dies. The types of welding we offer include:

- Angular (for frames, etc.).

- Front (for O-rings, profiles, tubes, etc.).

- Sheets, Bands, Sleeves, etc.

- Multi-component.

- Final product solutions with multiple materials.

Most Common Silicone Molding Products

- Frames

- Molded gaskets

- O-rings of any size

- Bellows

- Plugs

- Bushings

Silicone Molding Tolerances at Merefsa

Our quality in all molding processes and tolerances is the most precise on the market, which allows us to offer the widest range of silicone gaskets, with the best quality and the most competitive prices in the sector.

There are three types of internationally accepted molding tolerances ("M"):

- Class M1 = Maximum Quality

- Class M2 = Good Quality

- Class M3 = Non-Critical

Standards and Certifications: We ensure that our products meet general standards and the most stringent manufacturing certification regulations, including:

- ISO 9001 and ISO 14001

- TS 16949, UNE-EN ISO 13485, OHSAS 18001

- ISO 3302-1