Milling and mixing

We have a silicone kneading section that can adapt to production volumes based on demand. In this section, we prepare silicone rubber raw materials and add additives according to the specific needs of each client. This kneading process can be carried out traditionally, using manual kneading machines, or automatically, with the latest generation of equipment available on the market. Thanks to this process, we guarantee high-quality standards in our semi-finished products.

We manufacture custom silicone bases for clients who require tailored solutions. Simply tell us your needs, and our team will be happy to advise you on finding the most suitable silicone.

Application of Formulations to the Kneading Process

The professionals in our kneading lines bring their extensive experience and apply the formulations developed by the chemists in our Quality Department to the manufacturing process. Thanks to this approach, we can offer customized solutions to each of our clients, adapting to their specific needs:

- Curing with platinum or peroxide salts.

- Shore A hardness range from 20˚ to 85˚ in VMQ silicone.

- Silicone foam density from 0.15 g/cm³ to 0.80 g/cm³.

- Possibility of incorporating various additives, such as HT (for temperatures above 250ºC), THT (for temperatures above 300ºC), steam additives, conductivity, high mechanical resistance, high transparency, and fluorosilicone.

- COLOR solutions, adapting to the desired transparency and the RAL number required for the final product.

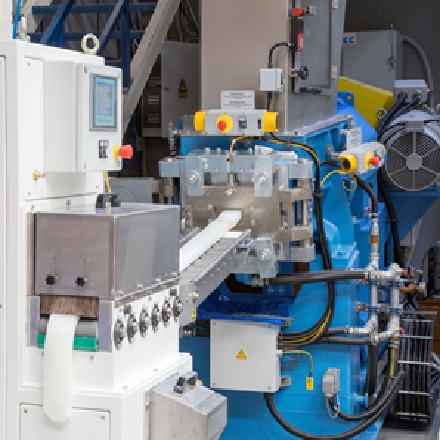

Automation in the Silicone Kneading Process

At Merefsa, we carry out the kneading process with a delivery time of less than two weeks for all types of bases. Thanks to our state-of-the-art kneading machines, we can work with various silicone variants, such as:

- Standard insulating silicone (MVQ).

- Conductive silicone.

- Steam silicone.

- Fluorosilicone (FVMQ).

- High-temperature silicone (THT).

- Low-temperature silicone (PMVQ).

- Platinum silicone.

- Food-grade silicone, complying with FDA CFR21 section 177.2600 and BgVV (Recommendation XV) regulations.

- Medical-grade silicone, complying with USP Class VI.