Wire EDM process - Silicone extrusion dies - Merefsa

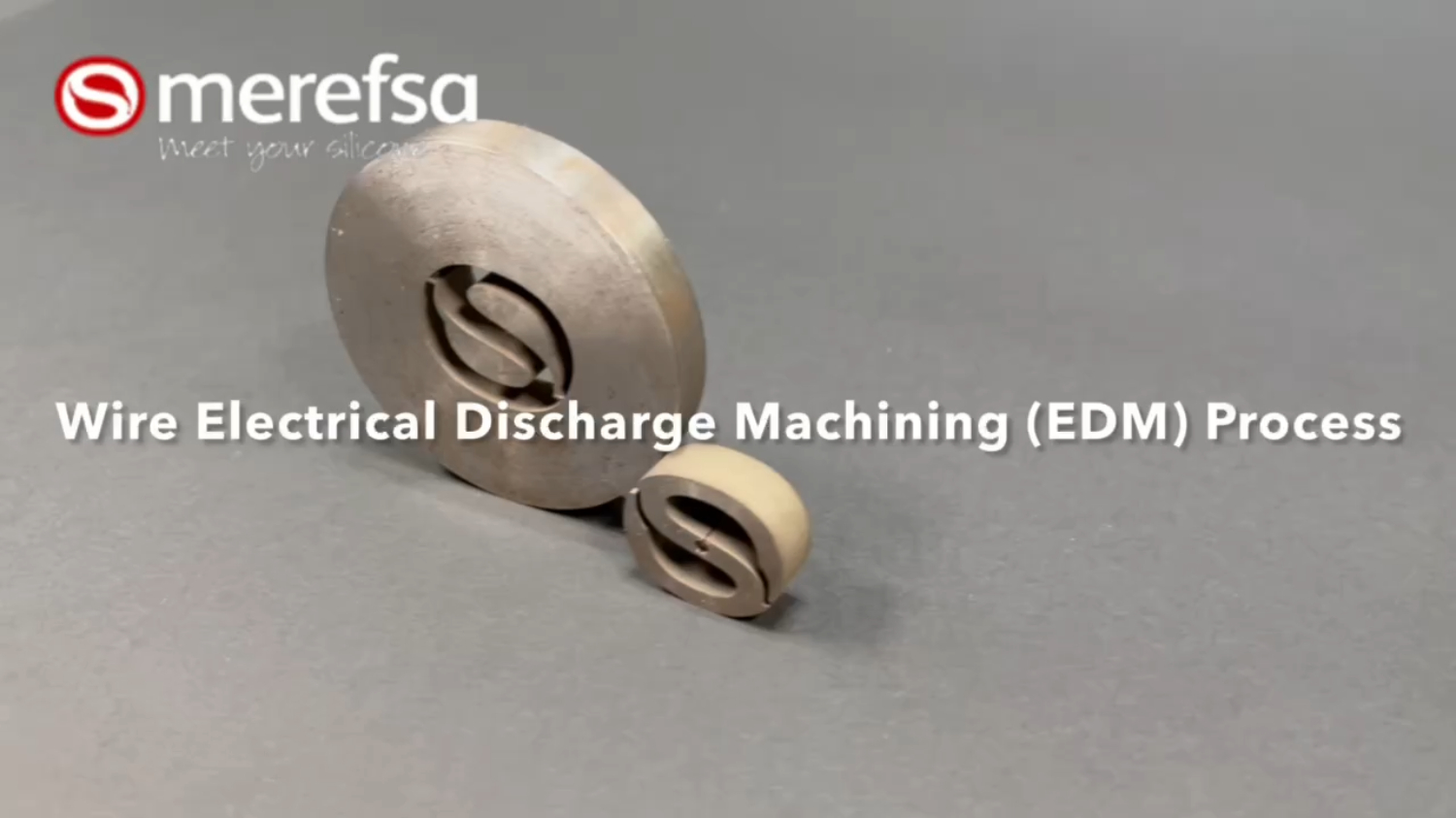

Manufacture of dies by EDM wire EDM.

We show the EDM wire EDM process in which we visualize how a die is manufactured to extrude a silicone profile from a metal support which is given the previously designed shape. Our machining plant has the latest technology in wire EDM +GF+ machines. Electrical discharge machining EDM is an extremely precise manufacturing process that uses electrodes, dielectric fluid and an electric current to cut metals. This video shows all the processes involved in the manufacture of a silicone extruded profile: the design process in the Technical Office, the process of creating the die for the wire EDM extruder nozzle and the final extrusion of the weatherstrip.

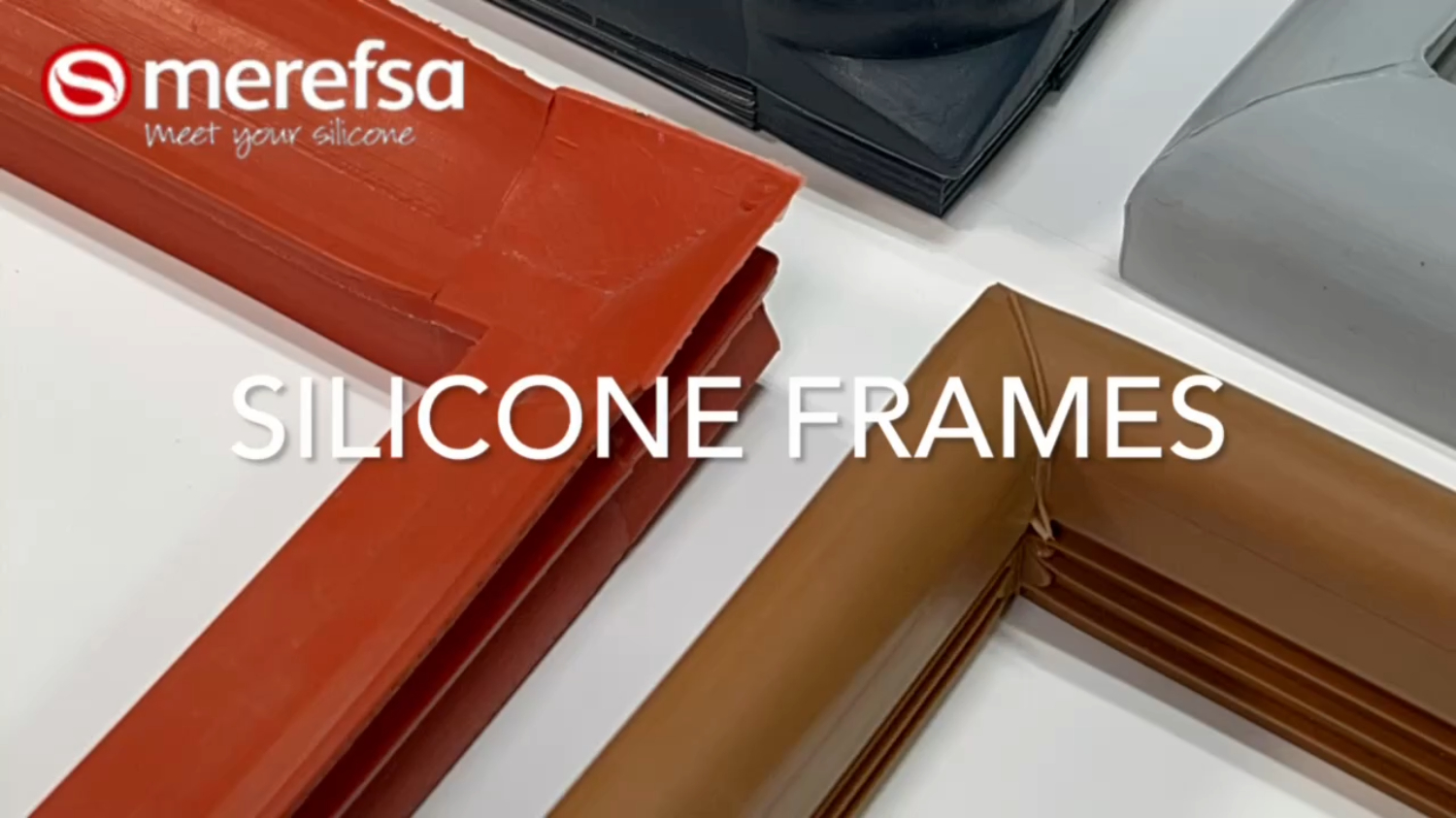

Merefsa is one of the largest manufacturers of silicone profiles in Spain. They comply with FDA certification. With our extensive experience, the Technical Office and machining departments design and can manufacture dies to produce this product in almost any geometry and specifications. We have nearly 4,000 different silicone profile extrusion dies, also known as silicone weatherstripping, including shapes as diverse as T, h, e, P, L, U, OO, autoclave, scraper, etc. The main applications of silicone profiles are sealing gaskets in all types of industries and processes, although the field of application in industry is almost infinite. It is used as electrical insulation, inflatable gaskets for autoclaves, sealing gaskets for the lighting industry, gaskets for insulating oven doors, enclosure gaskets for aluminum profiles, gaskets for dyeing autoclaves in the textile industry, welding profiles in the manufacture of plastic bags, embellishing profiles in any industry, etc. We can also manufacture them in detectable silicone, steam, platinum, fluorinated, etc. and approved with FDA certification, being perfect for use in the food and pharmaceutical sector.