Molded / Welded Silicone Gaskets

- Product Information

- Fabrication

- Standards

- Images

- Available Products

At MEREFSA, we specialize in the manufacture of custom molded inflatable silicone gaskets, as well as rubber gaskets and welded o-rings, offering customized solutions for industrial applications that require precise sealing and high resistance.

Product Information

Our silicone gasket manufacturing process using hot compression molding and welding allows us to supply any type of shape according to drawings or samples, adapting to small, medium, and large production runs, with the option to include textile, metal, or bi-component inserts. After the vulcanization process, the silicone parts are post-cured in a hot air oven with forced circulation, ensuring optimal resistance and material quality.

We have our own section for mold, tooling, and die manufacturing, equipped with electro-erosion machines, milling machines, CNC, digital control lathes, and automatic lathes. This enables us to offer a highly efficient and dynamic service, with reduced delivery times and highly competitive prices.

Fabrication

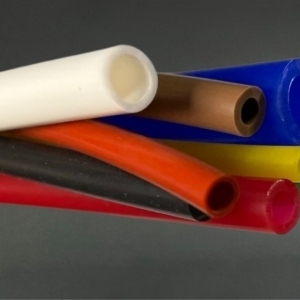

Using hot welding and molding vulcanization, we manufacture closed silicone gaskets in different formats for various industrial applications. We produce circular gaskets with a single weld, ideal for autoclaves and ovens, as well as silicone frames welded in a rectangular shape with four welds. Additionally, we manufacture custom silicone gaskets, including inflatable and vacuum gaskets, with options for "T" splicing or metal valves for air intake and exhaust.

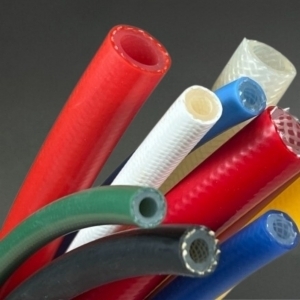

We have a highly specialized team for the fabrication and cutting of silicone gaskets, which allows us to ensure precision and quality in every piece. Thanks to our advanced machinery, we perform silicone gasket welding tailored to customer requirements, enabling the manufacture of silicone sleeves for discharge, both in cylindrical and conical formats.

Standards

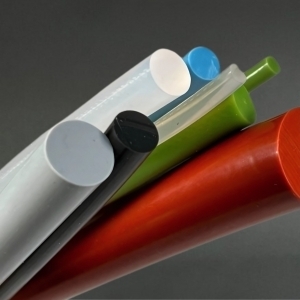

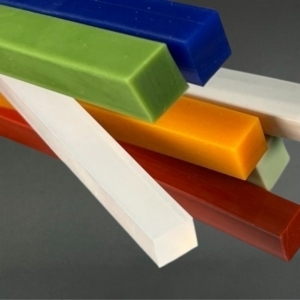

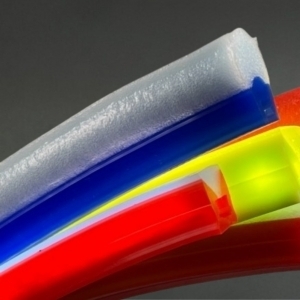

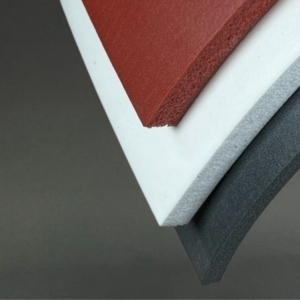

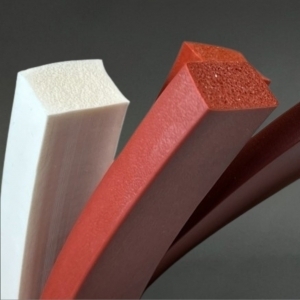

Our standard manufacturing is done in 60 Shore A compact silicone in translucent color. However, we offer the possibility to manufacture from 20 to 90 Shore A in any basic color or custom RAL shade starting from 25 kg, including options in luminescent, fluorescent, or metallic colors.

Additionally, we can manufacture silicone parts and gaskets with different types of bases, adapting to the specific needs of each application. For example:

- Standard insulating silicone (MVQ)

- Conductive silicone

- Steam silicone

- Fluorosilicone (FVMQ)

- Silicone for very high temperatures (THT)

- Silicone for very low temperatures (PMVQ)

- Platinum-cured silicone

- FDA food contact compliant silicone

- BgVV (recommendation XV)

- Medical grade silicone with USP class VI

- High-temperature standard sponge silicones

- Food contact compliant sponge silicones

Our manufacturing capacity allows us to offer customized solutions with high-quality materials, ensuring performance, durability, and compliance with international standards.

Imágenes

-

SILICON PLUG BLUE RAL 5015 55 SH° (±5) Ø25, (Ø40,70x28 mm)

| Stock: 7 U | P.V.P.: 5,50 € / U (VAT not included) | Term: 1/3 days | Ref. TSBL55M25407028

SHOPStock: 7 U -

JUNTA TORICA SILICONA ATOX AZUL (RAL 5017 APROX) 60 SHº (±5) MOL.96913R Øe 114.2mm X Øi 102 mm X 6.1

| Stock: 25 U | P.V.P.: 14,70 € / U (VAT not included) | Term: 1/3 days | Ref. JSBL65MOL96913R

SHOPStock: 25 U -

SILICONE JOINT FDA GREY 50 SH° (±5) MOL. 11185F Øe 26,15mm - Øi 7,5mm X Øe 10,4mm - Øi 2,5mm

| On request | P.V.P.: 5,69 € / U (VAT not included) | Term: Request | Ref. JSGY50MOL11185F

SHOPOn request -

BLUE SILICONE GASKET FOOD GRADE (RAL 5017) 65 SH° (±5) MOL. 96913BB 119,95 mm X 99,65 mm X 5,55 mm

| Stock: 23 U | P.V.P.: 16,30 € / U (VAT not included) | Term: 1/3 days | Ref. JSBL65M96913BB

SHOPStock: 23 U -

JUNTA MOLDEADA SILICONA ATOX. AZUL 50 SHº (±5) MOL. 96931A Øe 164,80mm x Øi 144mm x 9 mm

| Stock: 15 U | P.V.P.: 11,93 € / U (VAT not included) | Term: 1/3 days | Ref. JSBL50MOL96931A

SHOPStock: 15 U -

WHITE SILICONE O-RING FDA 60 SHº (±5) Øi 380 mm X 3 mm

| On request | P.V.P.: 2,02 € / U (VAT not included) | Term: Request | Ref. JTSWH6040965B

SHOPOn request

On request

If the product is not available, please indicate the features you need ...