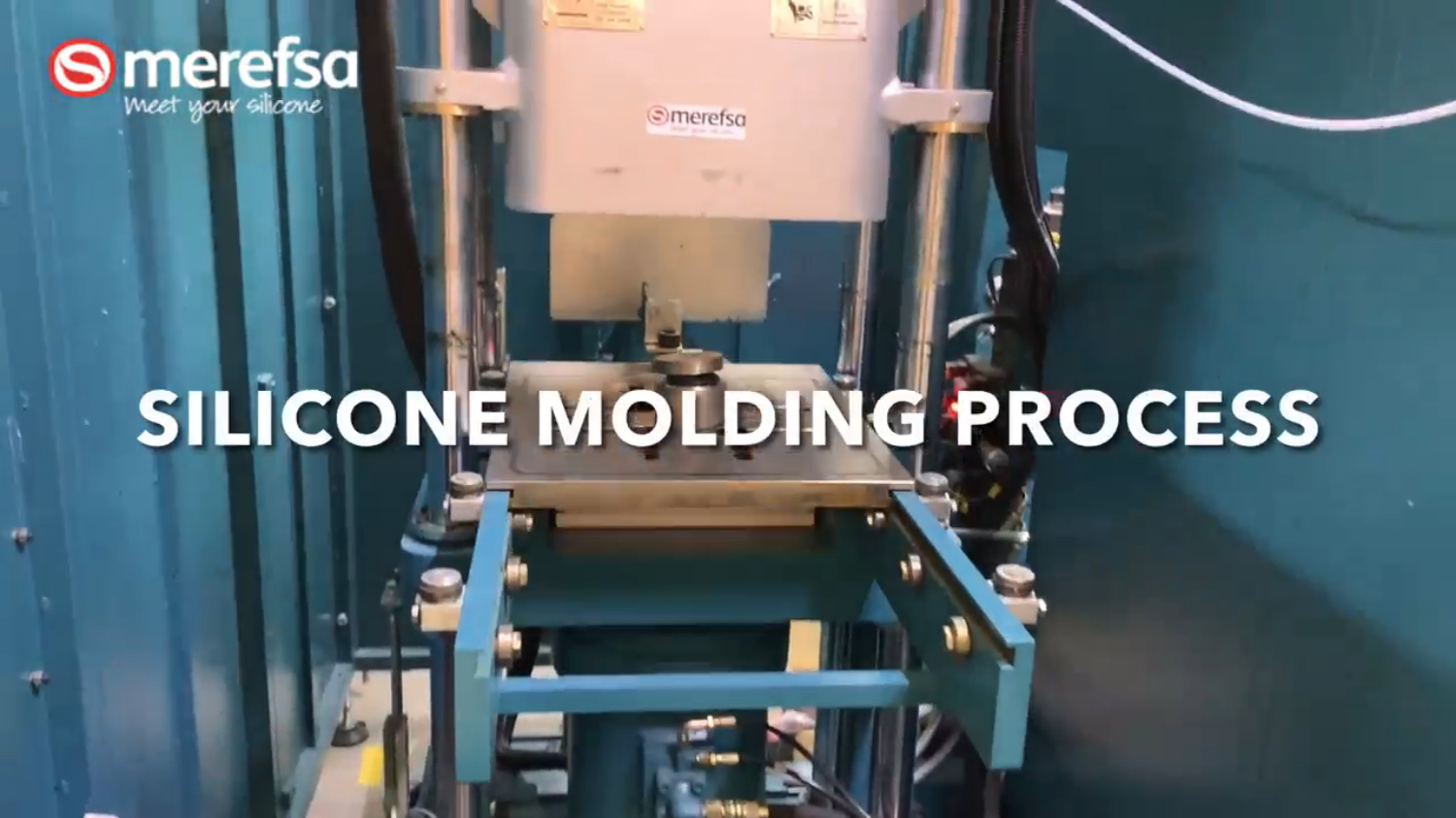

Molding process in MEREFSA - Double station compression molding machine

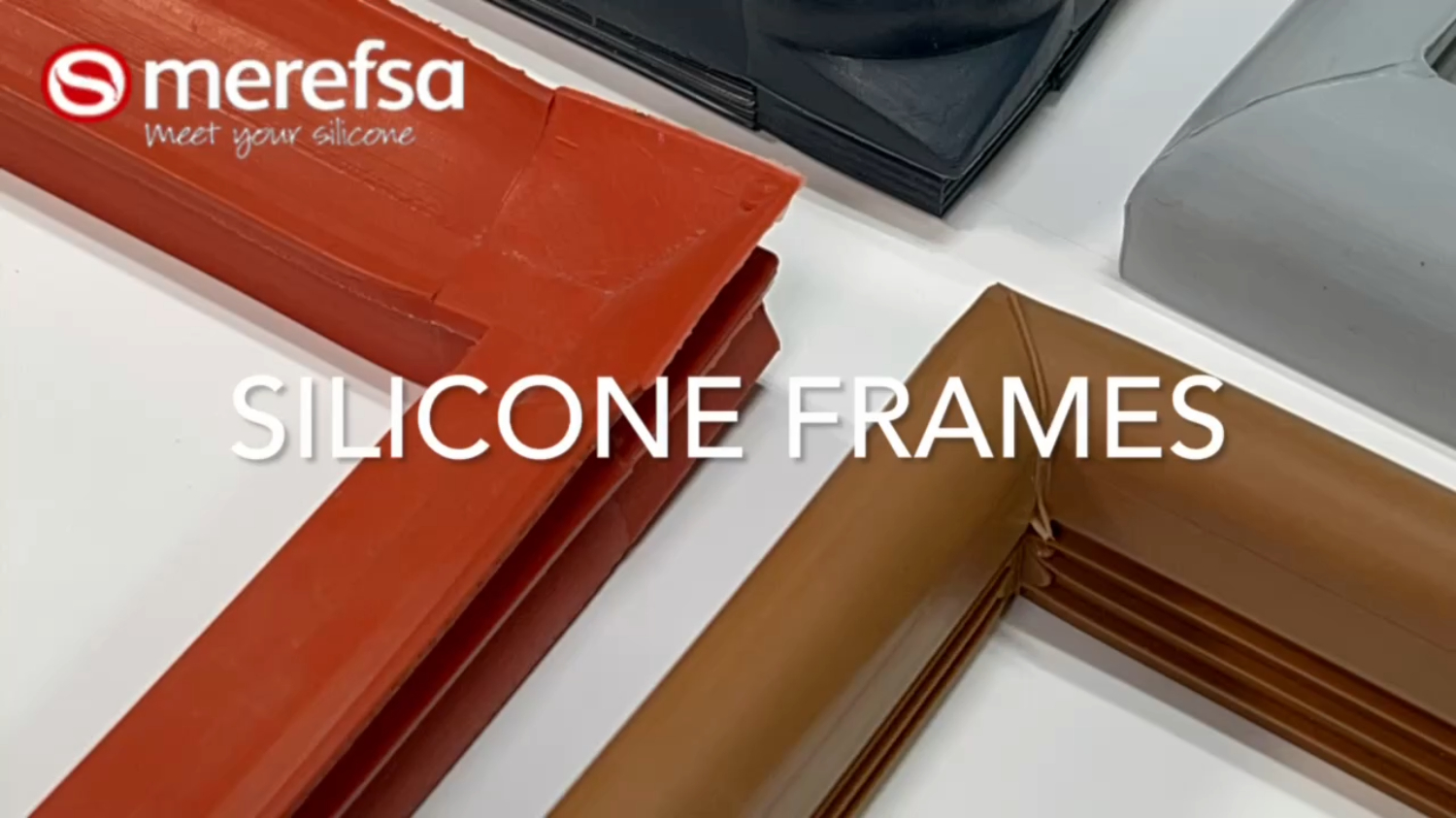

Merefsa has an important section for silicone molding and offers customized solutions with any hardness, color and additive. This time we show some of our silicone compression molding double station presses with mold capacities up to 610mm x 570mm. Our hot compression molded silicone gaskets manufacturing process allows us to supply any type of shape to a drawing or sample, both in small, medium or large series, with or without textile, metallic or bi-component insert.

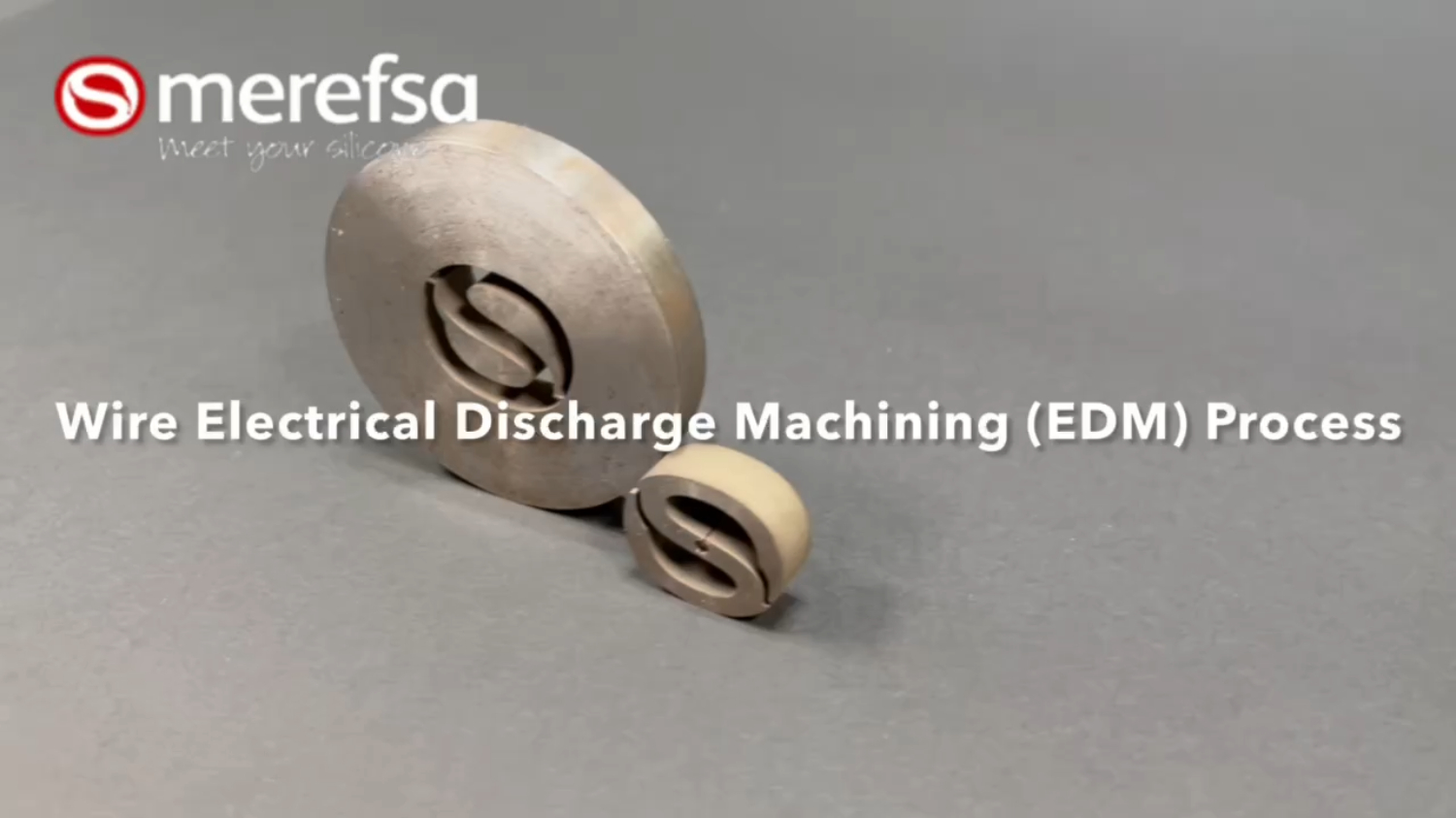

Our Engineering department always proposes the technical solution most adapted to your needs, with high quality criteria, competitiveness and tight delivery times. In our facilities you will enjoy the help of a highly qualified team, committed to your project and the latest technology. We can manufacture any single or multiple cavities mold, developed and produced entirely in our machining section. In this, we have all kinds of last generation machinery for the manufacture of molds, tools and dies, such as wire or penetration electro-erosion machines, 4 and 5 axis CNC, digital control lathes and automatic lathe, systems cutting, etc.