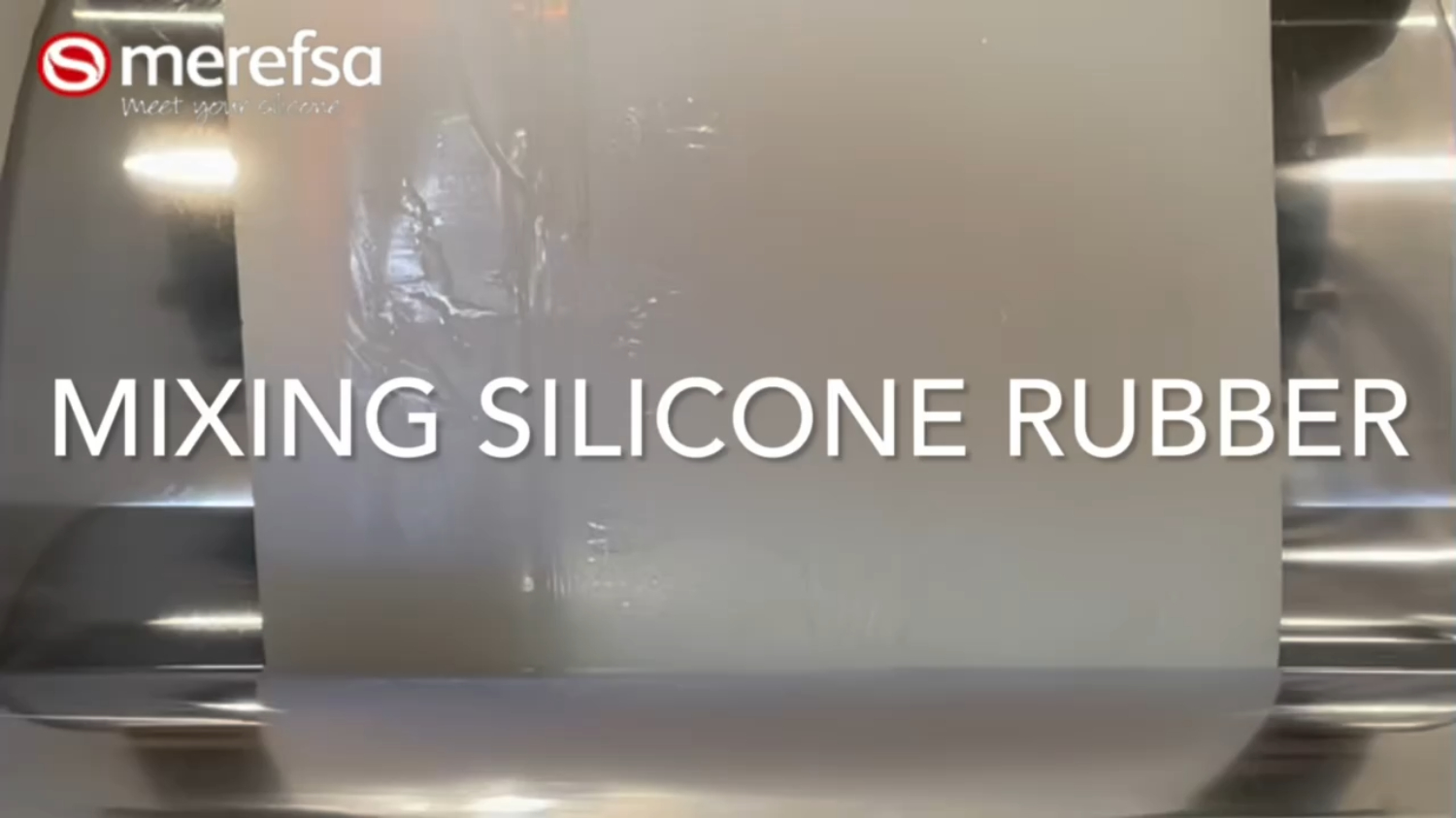

Mixing Silicone Rubber process Merefsa

Mixing of silicone rubber in manual grinding machine and mixing of silicone rubber in automatic grinding machine.

We show the process of silicone rubber blending, mixing of the silicone rubber loaded in a machine where counter-rotating steel rollers knead it together with additives and colorants until it becomes a perfect product for the extrusion or molding process of silicone profiles, tubes and parts. Also shown is the automatic mixing of silicone rubber in a kneading machine that kneads in a conical chamber with a large diameter screw and produces silicone strips perfect for direct incorporation into our plant's silicone extrusion lines.

In Merefsa's silicone rubber finishing section, we have machinery that allows us to optimize manufacturing times and guarantee a perfect finish on our silicone rubber products . In the process of mixing or blending, the silicone rubber becomes softer and easily assimilates additives such as oils, pigments, vulcanization chemicals, etc., making it a perfect compound to incorporate in our extrusion lines of silicone tubes and profiles or compression molding of parts. Silicone is an inorganic synthetic elastomer with excellent chemical and mechanical properties. It is stable and resistant to high and low temperatures (range from -60 °C to +300 °C). Depending on the combination of these additives we can enhance different qualities. This video shows how silicone rubber is mixed with these additives and perfectly dyed in various colors. At Merefsa we are market leaders in high transparency silicone. We can manufacture custom silicone formulations and we have the ability to adapt the color of the compound to the RAL number requested by the customer. What color do you need, Merefsa does it.